*Unimat Pix Page*

Pix from Unimat Hobbyist

Machines and How They Use Them

This is your Page!

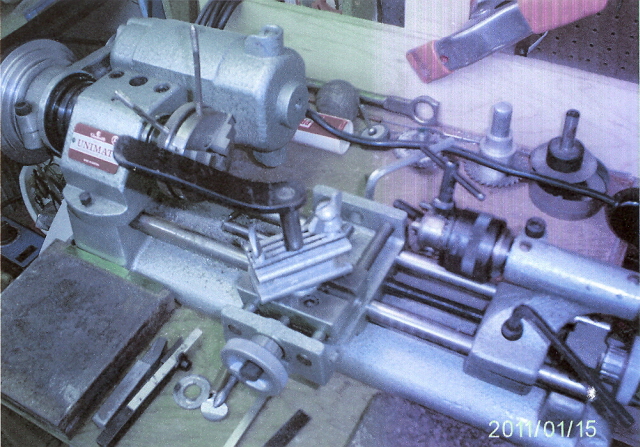

Nice, Sl 1000 From, Izzy Cruz 3. Sweet set-up with Quick change tool holder, Love that magnifier!

Jim Rizzuto, Hawaii, I use the lathe to shape and polish cast resin fishing lures. Check out the lures on the cover of our latest book. I made all of those with my 10- and 12-year-old grandsons.

Rufus, Atlanta, I have had my machine for nearly 40 years. I built a mahogany case to hold the machine and all of its accessories years ago so I could take it along on the road when I had to go out of town on business. The drawers lock and the case can be closed and latched. All needed tooling is in those drawers. The attachments are held in with knurled brass "nuts"and are positioned to clear the machine when the case is closed. I know those hotel maids wondered what hose metal shavings on the carpet were all about in the morning. It is truly a "machine shop in a suitcase"!

Juan C Pepper, Lima Peru I have just started to put in order my workshop after more than 5 years. I've just move back to my old house, where I have the space needed.

I have a Myford Super 7, two Unimats, a vertical drill, work tables and lots of other tools.

The two Unimat were my fathers, a great enthusiast for models. One of them, he got it around 1950 and the other in the 70's. They are in very good shape.

It is a simple but precise machine, that's what it makes it unique.

Just for the record the cartridge case being trimmed is a 45-70.

The case fixture was removed from a manual trimmer and modified to fit on the milling table.

The cutter head is also a stock item that has been modified for the job. And of course all

the lathe work to modify these tools was done on the unimat.

Dave Hamilton, Omaha I have yet to run across any of my shooting fellows using any kind of lathe at all for this purpose. Typically I can trim a case in about 3 seconds, I have a home made device next to the lathe that has two rotating cutters to bevel the inside and outside of the case after trimming. With this setup I get about

10-12 cases per minute trimmed and beveled. When you are looking at quantities from hundreds to thousands this really takes the work out of the job, plus you just can't get it any more accurate and consistent as the unimat with other tools.

If you would like to share Pix of how you use your Unimat , E-mail me & I'll post it here. Have Fun, Doug

E-mail : [email protected]

DF. 2026

Charlie Sauter, Ohio

Thanks for your e-mail and for making the belts available to us Unimat lovers. I received mine some 44 years ago as a Christmas present from my parents. At 13 years old they thought it a bit strange that I wanted a lathe but, looking back, I think it was the best present I ever received. I don't use it a whole lot any more but when needed it sure comes in handy, and I have never lost the excitement of turning out a good looking part. I have attached a couple of photos from my latest project--made a spinner for an 18" wing span rubber-powered stick and tissue P-51 that I have flown in competition--best time 2 min 3 seconds.

Charlie's, beautiful balsa and fabric P-51, takes me back to a younger day!

Dave Stewart, Maine

Dave, Uses his Unimat and WW lathes every day in his Clock Shop.

Says, his DB 200 is the hardest worker!

Nice shop, Dave. Everything needed is at hand!!

Please have a look at these other pages of interest on my Unimat web site:

Here are some pix of my Sl at work

This project was making a contact insulator from extruded acrylic.

Part for restoration of Blinker switch for 1952 Porsche 356 Pre-A coupe.

Dennis from Cyprus

Sent these pix of his beautiful creation...

My Unimat, which I bought in 1971, is still working well despite having to convert electricity to European 240V.

FYI, I'm attaching 2 photos of my recently completed "scratch" model of Sea Scout 44' Ketch "YANKEE CLIPPER" I sailed on in 1951 and which is still sailing on Puget Sound. The model is 22 inches long. I used the Unimat extensively for making metal and wood parts.

Cheers, Dennis